BYU Creamery

November 2024

Bulk Ice Cream Package Label System

Overview

This project was less about visual design and more about systems thinking and automation. I took the initiative to streamline the BYU Creamery’s nutrition label production by combining Adobe InDesign with spreadsheet-driven automation. The result: dramatically reduced production time, fewer errors, and a team freed to focus on higher-impact creative work.

ROLE: Lead Designer

The Problem

Before automation, every nutrition label was built by hand in Adobe Illustrator—typing numbers, adjusting layouts, and double-checking every detail across more than 30 individual data elements per label. A single label could take anywhere from 45 minutes to 2 hours, and big batches ate up entire days. It was repetitive, error-prone work that pulled time and focus away from higher-value creative projects.

My Approach

This was a workflow engineering challenge disguised as a design project. The real win here was in system thinking—designing a process that automated repetitive tasks without sacrificing quality.

I saw an opportunity to dramatically improve efficiency by moving away from Illustrator’s manual layout process and leveraging Adobe InDesign’s automation capabilities. My goal wasn’t just to speed things up—it was to build a sustainable, scalable system that would keep quality standards high while minimizing repetitive work.

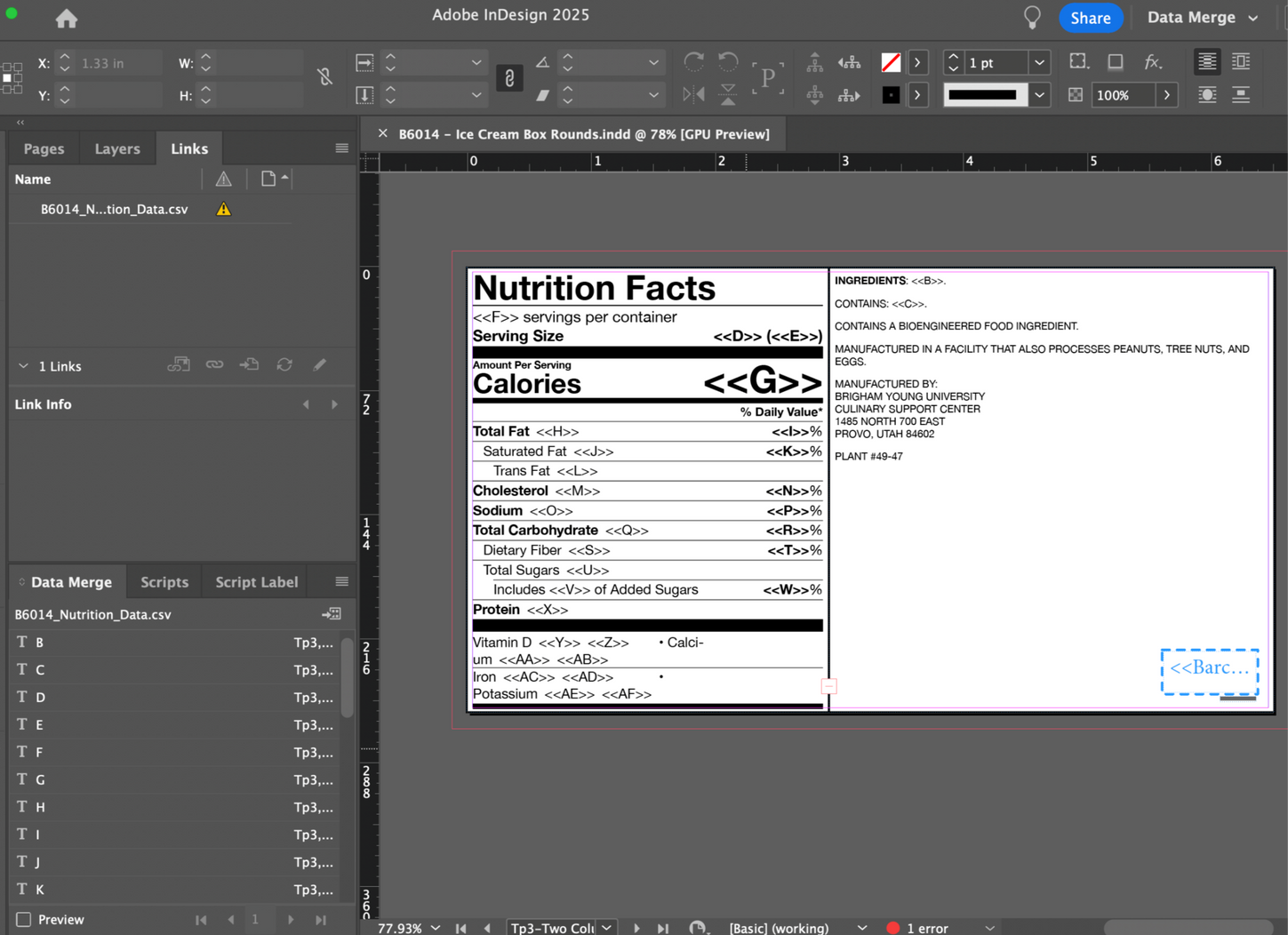

Master Template – Designed an FDA-compliant nutrition facts panel template in InDesign with precise formatting and integrated barcode placement. This became the foundation for every label going forward.

Centralized Data Source – Built a single CSV spreadsheet containing all product details—nutrition data, product names, UPC codes, and linked barcode images—so updates could happen once and instantly apply across every label.

Barcode Integration – Generated UPC-A barcodes via barcode.tec-it.com using codes provided by my project manager, then linked them directly into the CSV for automatic placement in each label.

Data Standardization – Created lightweight VBA macros (with ChatGPT’s help) to clean and format nutrition data, ensuring consistency and reducing errors before it ever reached the layout stage.

The initial planning and setup took careful thought, but once the system was in place, production speed and accuracy skyrocketed.

Overview

This project was less about visual design and more about systems thinking and automation. I took the initiative to streamline the BYU Creamery’s nutrition label production by combining Adobe InDesign with spreadsheet-driven automation. The result: dramatically reduced production time, fewer errors, and a team freed to focus on higher-impact creative work.

ROLE: Lead Designer

CLIENT: BYU Creamery

November 2024

Tools Used

Bulk Ice Cream Package Label System

Results & Impact

Label production time dropped from up to two hours to just 5–10 minutes, with far fewer errors and consistent formatting across every product. The freed time let the team focus on creative, high-impact projects, and the system scales easily—new products or updates are as simple as editing one spreadsheet.

And this approach isn’t limited to nutrition labels. The same workflow can streamline:

Business cards

Event name badges

Instruction manuals

Price tags

Product catalogs

Certificates & awards

Direct mail campaigns

Real estate flyers

Inventory tags

Anywhere you’re producing high-volume, data-driven layouts, this workflow can turn hours of repetitive work into minutes.

Conclusion

This project wasn't about visual design—one of my amazing team members had already handled the beautiful label aesthetics. Instead, it highlights my technical problem-solving abilities combined with my understanding of design workflows. It shows how smart automation can multiply a designer's impact way beyond individual creative work—turning process optimization into a real competitive advantage.